Chapter 17

Camera - Monitor assembly

Les Robotham and R. Pedro have developed this project over a number of years.

The unit itself forms a self-contained combined camera and monitor, which at a

later date can be modified to produce video signals for external equipment.

No synchronising is required as the monitor and camera share the same disc.

A special disc is used having the holes distributed over one and a half turns to

ensure the image on the viewing section is the right way round. Construction is

not critical but it is important that external light entering the disc area is

kept to a minimum. Areas within the camera and detection head are sprayed matt

black to reduce reflections. Many variations have been made of this unit

including the 'hidden disc' 'biscuit tin' method where the disc is completely

enclosed, the only apertures being for the viewing area and the lens and

detection head.

What you will need for this project:

- Enclosure for disc and mounting base or cabinet

- Special one and a half turn spiral disc ( club sales )

- Power supply unit for motor and electronics

- Cassette motor. ( club sales )

- Motor speed control electronics

- LED cluster and LED driver electronics as in the monitor

- Detector head assembly including electronics

- A suitable lens ( see later )

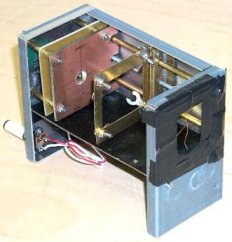

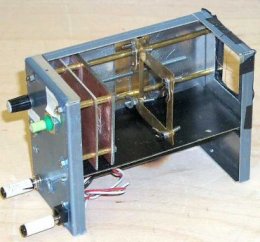

Enclosed disc and cabinet

Top view of cabinet, in the right half the monitor part, in the left half the

camera part.

The disc is enclosed by an internal partition and the front of the cabinet with

rectangular cut-outs.

Whilst the design is not critical, stray light must be kept out of the area

between head amplifier section and the disc. This is achieved by spraying all

the inside of the box matt black. The advantages of the square box are that

different scanning formats can be achieved, either by changing the direction of

motor, reversing the disc or positioning the box in another plane.

This box contains all the sub-assemblies, and can also house the power supply,

if you decide to build this into the unit. You may however decide to enclose the

disc totally in a light-proof unit and mount all the peripherals on the outside

of the unit.

The disc

The club disc has a spiral of 48 holes over 1½ revolution. The camera

masks the inner 16, the monitor the outer 16 holes. In this way camera and

monitor share the same disc. There is an extra circle of 32 sync-holes at the

rim.

Power supply

A 12-volt regulated power supply is required for the camera-monitor. As pointed

out earlier, extreme care must be taken when working with mains voltages. If

unsure use an 'off the shelf' power supply or seek advice from a more

experienced constructor. The power supply should have a minimum current rating

of 1.5 amps, which will be sufficient to drive all the electronics and a

cassette type motor (via the speed control circuit). Motors of a different type

may require a greater current and possibly a dedicated power supply.

The motor

Whilst in a monitor the incoming video signal controls the speed of the motor,

in a camera the motor speed controls the video signal. Different types of motors

can be used. The speed of an AC motor is governed by the supply frequency and

the number of poles on the rotor. Whilst a dynamo is normally a generator,

applying an AC supply it will act as a motor. At 50 Hz an eight-pole dynamo

will rotate at 750 rpm, which is the correct speed for NBTV. Whilst small motors

of this type are rare, a bicycle dynamo can be used, although it will need to be

turned by hand to start. By using dynamos on both camera and monitor the common

ac supply will keep both units in synchronisation.

The most popular motor used however is the small DC motor 'liberated' from an

old cassette recorder. It is important to ensure the motor has not got an

internal speed regulator fitted. If it has this can be easily bypassed. In its

simplest form a variable DC voltage is applied to the motor to vary the speed.

Improved speed control

The natural tendency of the motor is to slow down as the windings 'heat up'.

This can be prevented by running the motor not by a constant voltage, but by a

constant current. A constant voltage gives the motor a constant speed, but this

is affected by changes in the internal resistance of the motor. A constant

current gives the motor a constant torque. Then the speed is the result only of

the applied current and the friction of the air onto the disc.

The exact motor speed is judged by observing the spokes of a stroboscope disc

glued to the centre of the scanning disc and illuminated by the light from an AC

driven neon or fluorescent tube.

In 50 Hz supply areas an eight spoked strobe is seen stationary at 750 rpm, this

is 12½ Hz. In 60 Hz areas, including the USA and Japan, a 10-spoked

strobe should be used, which will appear stationary at 720 rpm, i.e. 12 Hz.

The parallel resistors of 18O Ω and 27O Ω define the coarse speed.

If the speed is too low, replace the 27O Ω for a lower value, e.g. 18O

Ω, if it is too high, replace the 18O Ω by a resistor of higher

value, e.g. 27O Ω.

Mount the LM317 on a heatsink to prevent it running too hot.

Monitor part

The next parts are the LED cluster and LED driver circuit. They are identical to

the televisor in the previous chapter. The sync pulse circuit and automatic

motor synchronisation circuit are not needed. The video input is connected

directly to the output of the head amplifier, which is a separate unit.

The head assembly

The next module to build is the head assembly. The main case is available for

those in the UK from Maplin. The drawing shows the general layout of the

prototype unit.

A lens mounted in this unit focuses the light onto the photo sensor. A screwed

rod facilitates adjustment of the lens from the outside of the unit. Information

on the required optical arrangement is given in the chapter on Optics and Lenses.

The solar cell and head amplifier

The dome cell is mounted behind the condenser lens directly in line with the

axis of the lens assembly in order to focus correctly. The sensor leads need to

be kept as short as possible with the associated variable load resistor

contained within the same small screening box as the head amplifier. The circuit

has a low impedance output. Patrick de Scheemaecker and Keith Vickers designed

this pre-amplifier circuit.

Owing to the high gain (around 85dB) good RF techniques should be used in the

construction of this amplifier. The 22k variable sensor load enables the input

level to the amplifier to be ad-justed. This affects both the sig-nal and noise

level and acts as a sub-stitute iris control.

Further gain adjust-ment, if neces-sary, can be achieved in the subsequent

video/sync mixer. It is normal that the amplifier takes around ten seconds to

stabilise after switch-on. The video output from this unit, which does not

contain any synchronising signals, could be fed directly into the LED driver

circuit.

Finishing the head assembly

Care should be taken to provide adequate screening. This will help avoid

feed-back, RF pick-up and mains hum problems. A hole just large enough to fit

the dome sensor is needed in the front face of the head amplifier screening box.

Further holes are needed for the +12-volt DC and video output leads, and to

allow adjustment of the sensor load.

To minimise internal light reflection within the head assembly the internal

exposed metalwork must be sprayed matt black. Small spray cans of this are

available from most hardware outlets.