Chapter 4

Building a complete NBTV disc televisor

As with most hobbies the beginner's first question is where do I start? We

recommend you to build first a disc televisor and use the club CDs as a signal

source. From then on it's up to you how comfortable you are tackling the project.

Remember not to take on too much at a time.

When you have a working system you may wish to move on to a camera or an

electronic pattern generator. All the circuits in this book have been selected

for their proven track record. Where possible printed circuit boards are

available to ease construction. The project may be as 'minimalist' as the one

shown here. Peter Smith has constructed a disc televisor to show how simple it

can be.

|

|

Front view of Peter Smith televisor. The electronics is placed on the

base board. |

Rear view of the televisor. The motor is held on a post with a side

support for the LED cluster. |

And here you see the typical layout of the different components of a Nipkow disc

televisor in top view.

You may however wish to spend even more time and produce a more elegant version

as shown here.

|

|

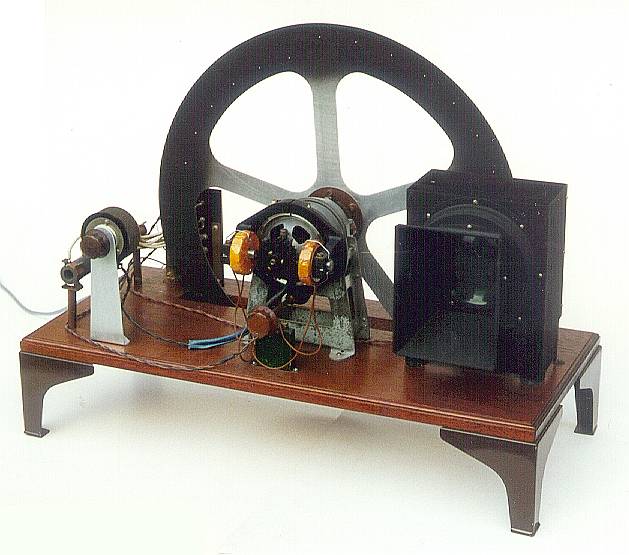

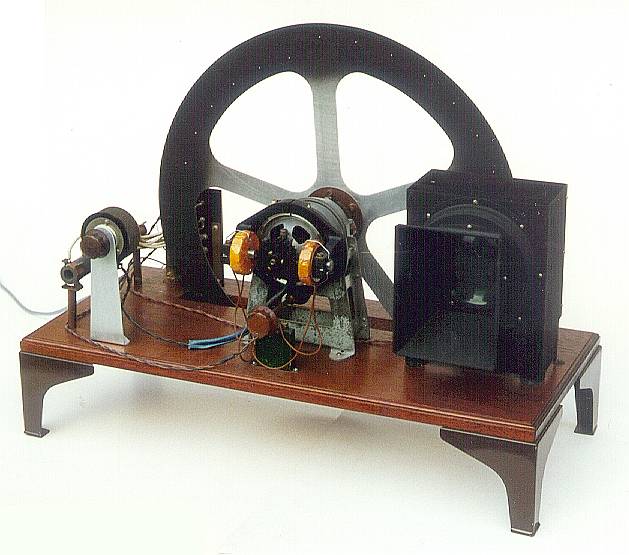

A replica of a Telehor receiver built by Denis Asseman of Belgium. |

A replica of the Baird Televisor built by Peter Smith. |

As you gain experience you may wish to tackle a larger televisor using a more

powerful motor and brighter light source. The circuits to be described can be

adapted for use in a wide range of televisor sizes. The original Baird

televisors were constructed as a piece of furniture, you may feel you wish to

produce some elegant cabinetwork in which to house your televisor.

Building a complete televisor

The parts required for this project are as follows:

- Wooden base

- A pre-drilled disc (available from the club)

- A small DC motor (cassette motors available from the club)

- 12 Volt Power Supply

- Motor drive electronics (PCB available from the club)

- LED cluster as a light source

- A medium size magnifying glass

- LED drive electronics (PCB available from the club)

The most important part of the televisor is the disc; this will determine the

picture quality. Pre-cut discs are available from the club; these will give a

good picture as they have been produced on a numerically controlled machine to

the highest accuracy.

The construction of the televisor is not critical, the cas-sette DC motor is

affixed to the disc in the centre by a push fit plastic coup-ling available from

the club shop. It is then mounted on a frame which allows the disc to rotate

freely.

The LED light source

LED's or Light Emitting Diodes play an important role in the construction of

mechanical NBTV televisors. These now replace the now obsolete large neon lamps.

Choosing the correct LED's is almost as important as producing a good quality

disc. Whilst most LED's on the market will produce a picture of some sort,

bright LED's that modulate without a change of hue will produce a superior

picture. The luminous intensity of an LED is measured in millicandelas (mcd)

normally quoted at a typical forward current of 20 mA. Also the opening angle

of the beam of light is important. The total amount of emitted light is defined

by both. The higher the number of mcd's multiplied by the opening angle of the

beam, and the more LED's of course, the brighter the display will be.

The latest Al-In-Ga-P ultra bright LED's are well suited to NBTV operation. They

can replicate many small conventional bulbs due to their brightness. These LED's

carry warnings as the output light is strong enough to injure eyes when viewed

without a diffuser. Although relatively expensive, due to their efficiency a

cluster can be made of just six devices.

LED's are current operated devices. Normally they are wired in series with a

current limiting resistor. Each LED has a forward voltage drop that depends on

its light colour. For red it is about 1½ volt, for yellow and orange 2 volts and

for blue and white LED's about 4 volts. Orange high brightness LED's combine a

high efficiency with a good visibility and they match more or less the colour of

the ancient neon lamps. When placed in series it is important that the driving

power supply has a potential high enough to overcome the voltage drop of all the

LED's in the chain, else they will not illuminate.

The diagram at the left shows a suggested arrangement for yellow or orange

ultra-bright LED's, two chains of each three devices. Three yellow or orange

LED's in series drop 6 volts, so with a 12 V supply enough voltage remains for

operating the driver transistor. These LED's will withstand 50 mA in each chain,

so the driver has to provide 100 mA for max brightness.

The latest Ga-N devices give pure white display. For white LED's the voltage

drop is higher and the max current per diode is lower, 20 mA. In this case it is

better to place the six LED's in parallel, see at the right.

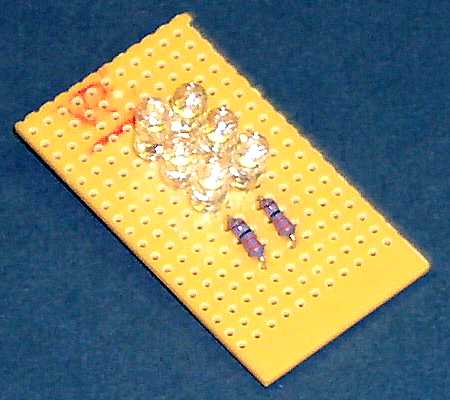

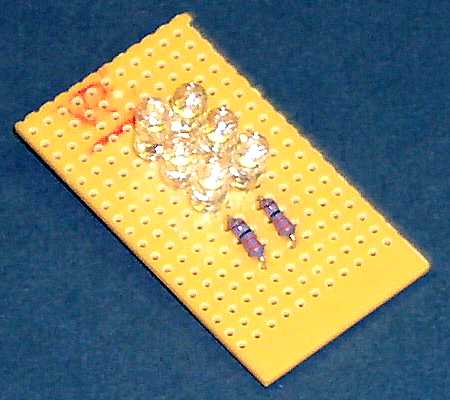

With the absence of a printed circuit board for this part of the project a piece

of 40 mm square stripboard will suffice. A spot face cutter is needed to isolate

the copper area not required. Holes drilled outside the display area will

facilitate mounting.

The LED assembly is mounted behind the disc. A suitably placed diffuser between

the LED's and the viewing area close to the spinning disc will allow uniform

illumination of the display area. Careful positioning of the LED's and the

diffuser is important to ensure the illumination is constant over the display

area. Mount a suitable magnifying glass in front of the disc.

A black viewing tunnel prevents surrounding light from falling onto the glass

surfaces and causing reflections.

Sync separator and LED driver

A composite NBTV video signal is fed into the input; this can be either from a

CD player using one of the club CD's or any NBTV source described in this

handbook. Please note that when using a portable CD player to play one of the

club CDs to use the 'line out' signal and not the headphone output, as some of

the quality is lost in the output audio amplifier.

The description of the circuit is as follows. IC1a and the IN4148 diode DC

restore the NBTV video signal on pin 2 of IC1a. The DC restoration level is set

by the potential on pin 3 of IC1a, i.e. 0 volts. The sync slice level is set at

67mV by the potential divider formed by R1 and R2. A clean positive-going sync

can be taken from pin 7 of IC1b to drive the motor circuit mentioned later. The

1k pre-set on pin 5 of IC2 enables the black level to be adjusted so that only

the picture signal from black to white is used to drive the LEDs. The brilliance

control is adjusted to give about 1 volt peak-to-peak across the source resistor.

This resistor can be changed in value to give the LED current required. The PCB

is available from the club.

Gamma correction

Although the current/brilliance characteristic of an LED is almost perfectly

linear, some correction is provided by two extra source resistors, each in

series with a diode. The 1N4001's resistor boosts the current at the top end

(0.6 V to 1.0 V) of the signal whilst the Schottky diode's resistor affects the

mid-range.

The LED driver circuit will work without these diodes, however they improve the

grey scale appearance of the picture, especially those originating from

electronic camera sources.

Automatic speed control circuit

*

* values can be changed to suit different motors.

This circuit compares the speed of the disc from a series of 32 holes in the

disc with a reference signal from the sync separator and LED driver board.

The motor speed is automatically adjusted to match the incoming video. We need

to mask off one of the 32 holes on the disc, the hole that passes the opto fork

when the spiral of scanning holes jumps to a new frame.

The only adjustment that may be required is the alignment of the opto speed

sensor. A gap of 8mm was chosen to give enough clearance for a wobbly disc yet

sensitive enough to cope with the small holes in the 12-inch club disc. If a

scope is not available, the output of the sensor can be monitored across R2

using an AVO multi range meter on the 100 V dc range. The voltage should be

greater than 10V when aligned with a disc sync hole and less than 2 V when

between holes. Some external light shielding of PD1 may be required,

particularly on the 12-inch disc, as the sync holes are near the periphery of

the disc and light can leak round the edge.

The component values indicated on the circuit diagram have been selected to suit

the small DC motor and 12-inch plastic disc available from the club. The

components shown with an asterisk can be changed to suit different motors and

supply voltages (see later information on building a larger televisor).

On the motor control PCB provision has been made for either a pre-set or fixed

resistor to act as the opto detector load (R2), to allow for opto fork

components with different characteristics to the types indicated on the diagram.

A 47 k pre-set resistor will be suitable for most alternative types of opto

detectors, including those contained within single package slotted opto switches.

Ideally a scope should be used to adjust the pre-set for best pulse waveform

shape (steep sides and a flat top). Provision has also been made for an on-board

12 V low power regulator for use when the voltage required for the LED and motor

is greater than 12 V. This PCB-mounted regulator is not needed for the basic

televisor where all the 12 V rails can be fed together from an external 12 V

regulated supply. In this case 'Vout' should be linked to 'Vin'.

The two PCB's have been made the same length and can be mounted side-by-side to

enable easy interconnection. A convenient way of connecting the ground planes

and uniting the two boards is to use short pieces of stiff wire to link the

corner mounting holes, as shown in the photo of the minimalist televisor. The

sync and +12V lines also need to be connected by short pieces of insulated wire.

Putting the monitor to work

After building up the circuits and interconnections apply 12 volts DC from the

power supply. Apply a suitable NBTV source to the input and the televisor should

burst into life. Take particular safety precautions with the spinning disc. Once

the video source has been applied the motor should speed up to synchronise with

the incoming video signal and some sort of picture should be seen. Attention

should be taken with the positioning of the opto sensor and transmitter with

relation to the synchronising holes around the disc.

Should the circuit not work, check circuitry and verify with an oscilloscope.

The LEDs should be observed to modulate with the incoming video. Check at the

output of IC1b pin 7 of the LED driver board that there is a 400Hz signal

present for a 32-line system (375 Hz for a 30-line system). Verify that a

corresponding signal is being received by the motor drive system (IC1 pin 3)

from the sync holes in the disc.

Building a larger televisor

The same circuits and general principles as described above can be used to

construct a larger televisor, e.g. using the club 490 mm metal disc, except that

some component values will need to be adjusted to allow for the greater current

required by brighter LEDs and a more powerful motor.

The LED driver circuit can be used to drive higher power LEDs such as the Luxeon

type. To drive a higher current it is necessary to alter the value of the

resistors in the gamma correction circuit in the source of the output FET. The

values given above (33O, 15O and 12O) assume that the LED cluster requires a

peak current of 100 mA. Suitable values for 350 mA, 700 mA and 1.4 A peak

currents are given in the table. The table also gives values for a single source

resistor, to replace the three resistors and two diodes, in cases where gamma

correction is not required.

If two or more LED's are used in series, and the total voltage drop across them

is more than about 6 volts, the supply voltage should be raised to provide a

sufficient operating voltage for the FET. For example, two Luxeon III 700mA

white LED's in series have a total voltage drop of around 8V, and so around 15V

should be used for the LED supply. The FET will require a heat sink at the

higher power levels.

The motor driver circuit can be used with some component changes to suit

different discs and motors. These components are marked with an asterisk on the

circuit diagram. Either a direct drive or belt drive motor system can be used,

the former generally being more straightforward if the motor has adequate

bearings to take the weight of the disc. Belt drive systems can also work well

provided belt slippage is avoided by using suitable pulleys and drive belt.

A motor that has been identified as suitable for directly driving the club 490mm

disc is a Smith Industries motor ref. FHM1207/04. In this case the logic supply,

motor supply and LED supply can all be connected together and powered from a 15V

3A supply (4 to 5 amps on start-up). The on-board 12V regulator should be

installed. Resistor R7 should be reduced to zero ohms. R5 can be changed to 2k2

to give a wider range of speed control, if required. The FET will require a heat

sink.

At the higher peak current levels it becomes necessary to reduce the value of

the resistor (R5) between IC2 pin 6 and the gate of the FET, to avoid unwanted

current limiting. However, this feature can be usefully employed to protect the

LED's from excessive current. Suggested values for this resistor are given in

the table.